Neodymium magnet motor is optimized with FEA simulation to ensure perfectly symmetrical magnetic flux in both directions of the cone’s run. Motor metal parts are CNC machined from solid and refined material for maximum magnetic flux linearity and minimum magnetic loss. This reduces distortion at high power levels.

25.5 mm CCAW (Copper Clad Aluminum Wire) double layer voice coil is wound on an aluminum former for exceptional power handling and compression-free reproduction, for even the most demanding musical passages. Non pressed cellulose pulp exponential cone has a vinylester resin coating, ensuring a perfect balance between rigidity, weight, and self-damping.

The cellulose pulp guarantees an extremely natural and linear reproduction in all musical passages, with an excellent extension at high frequencies without audible break-up. An aluminum dust cup fixed directly on voice coil former, increases and linearizes the extreme top of bandwidth.

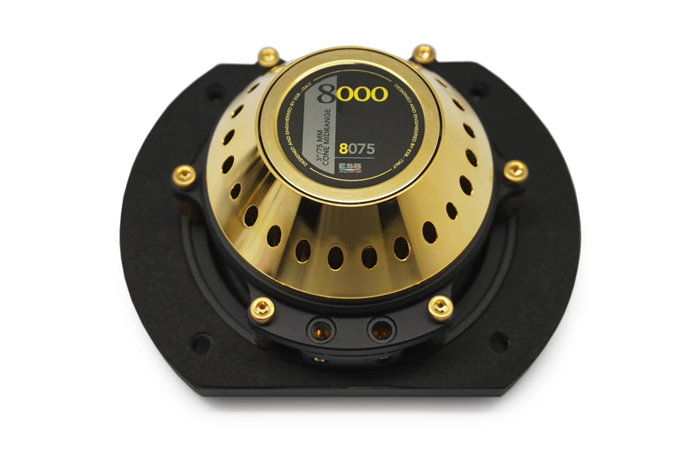

The CNC aluminum basket ensures a drastic reduction of the cone’s back reflections and a great torsional rigidity. High structural and torsional rigidity are a goal for perfect parts alignment, this requires very tight tolerances in the construction and assembling system.

That brings better efficiency, more power handling and less distortion. The exclusive rubber surround offers maximum linearity of travel and high reliability in extreme conditions.

The axial ventilation system ensures high thermal dissipation capacity, power handling and reliability. Large Conex™ spider allows a smooth and gentle run at low excursions, and gently holds the cone at high excursions, this increases the useful range of use. Exclusive terminal connection design can accept very large cables.